Coating

Dielectric coatings can be added to most parts. On MnZn cores; This coating serves as an insulator to prevent short circuit conditions and stray currents. Coating NiZn cores helps prevent abrasion of the insulation on wires as well as adding some level of impact protection. Parylene C is used for smaller parts while a thicker epoxy coating is used for larger ones.

Sorting

Despite tight quality control on standard parts; Some applications just need that extra peace-of-mind. Custom equipment is utilized for high volume automated sorting for both dimensional/visual specifications as well as electrical characteristics.

Laser Marking

High-powered fiber laser technology in order to provide for your marking needs quickly with a high degree of precision. With up to 30W of output power, a gradient of marking can be achieved from deep engraving to black marking which provides minimal surface damage. A high accuracy and focus can be met with our 3-axis control system, allowing marking on 2D planes and both simple and complex 3D shapes.

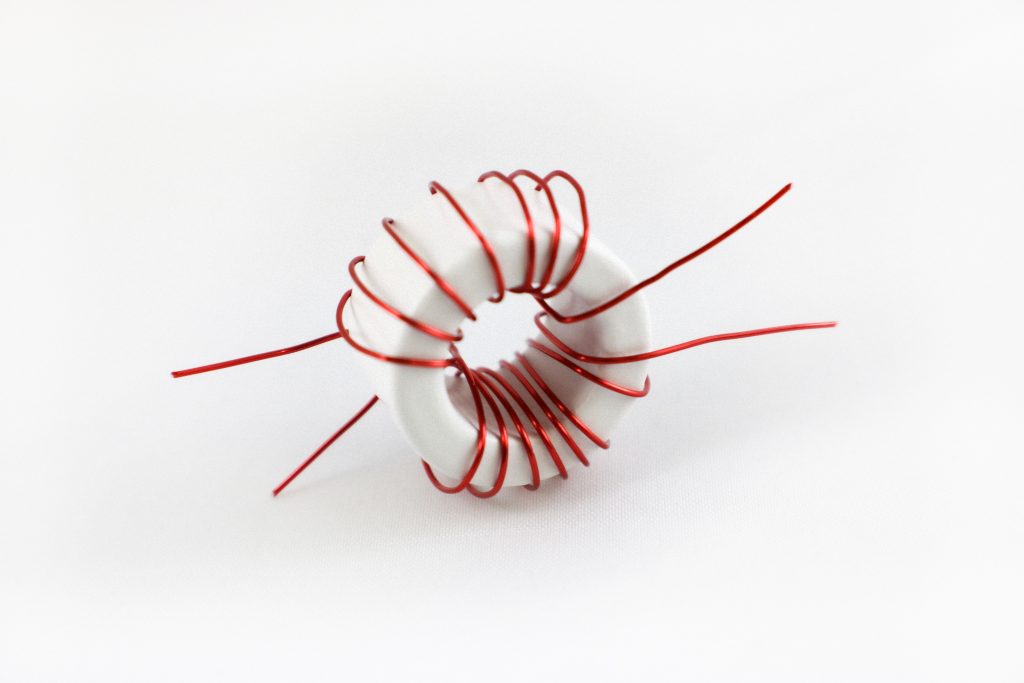

Winding

Prototyping to high volume production state-side and overseas of custom parts. Rods, Toroids, Multi-Aperture cores, Custom Ferrite configurations with thick and fine gauge wire.

Assembly

Component, Board, System Level Assemblies, Gluing/Assembly of ferrite cores.

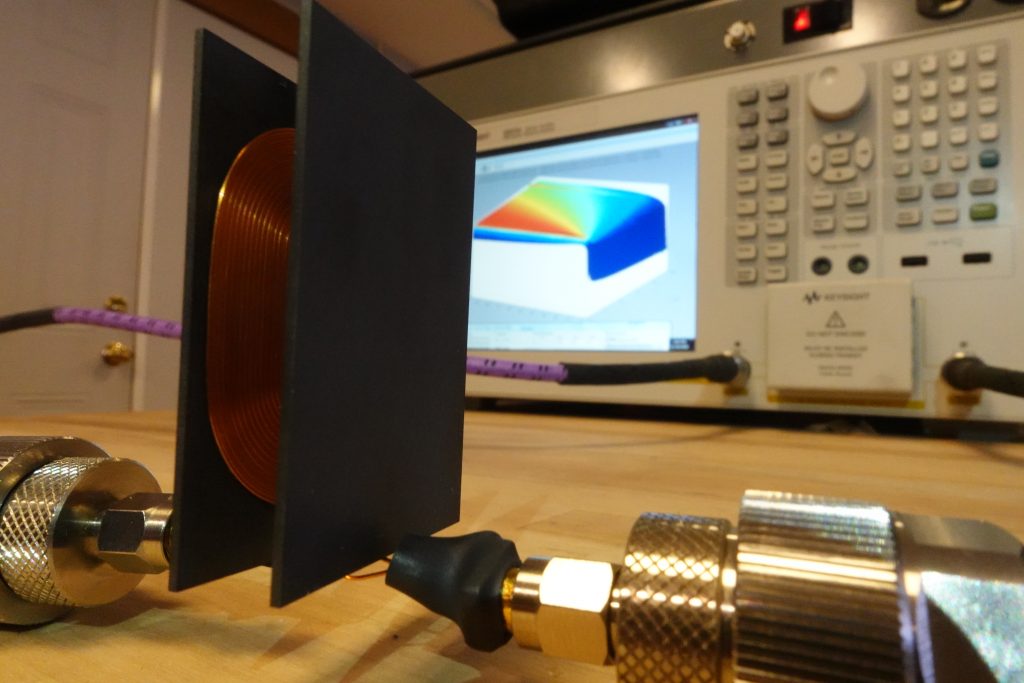

Testing

Application Specific Electrical Testing

Most relevant electrical characteristics can be accurately characterized using our state-of-the-art test equipment. In working with you and your application; The test parameters (environmental, circuit conditions) can be tailored to ensure testing accurately reflects real world performance.

Strength Testing

Using cutting edge force metrology equipment. With accuracies of down to 0.1N, capacities of up to 2500N (tension, compression) and the ability to perform complex multi-stage & repetitive stress testing cycles; Fair-Rite is able to test your parts and packaging to ensure that strength will not be an issue in your final application

Precision Measuring to 0.0005 mm

Use of our state-of-the-art measurement equipment allows us to quickly measure large parts (up to 200mm x 200mm x 150mm) with resolution down to 0.5um (micro meter) . Optical and coordinate measuring systems allow for measurement of complex geometries utilizing GD&T controlled features in an accurate and repeatable manner.

XRF (material composition)

Precise control of Ferrite compositions; can also be used to detect minute quantities of impurities in materials. The XRF method is widely used to measure the elemental composition of materials. Wide scan measurement allows for effective cross referencing of unknown samples.

Can’t find what you’re looking for?

At Fair Rite, we design, prototype and manufacture ferrite component exactly to your specifications.

Fill out the form below and we will contact you right away!

Or Call Us at 1-888-FAIRRITE