Toroids (5961001901)

61 TOROID

61 Material™

Inductive Components

Closed Magnetic Circuit

Printer Friendly Data Sheet

Check Stock

Part Number: 5961001901

61 TOROID

Explanation of Part Numbers:

– Digits 1 & 2 = Product Class

– Digits 3 & 4 = Material Grade

– 9th digit 1 = Parylene Coating, 2 = Thermo-Set Plastic Coating

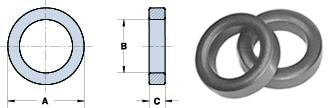

A ring configuration provides the ultimate utilization of the intrinsic ferrite material properties. Toroidal cores are used in a wide variety of applications such as power input filters, ground-fault interrupters, common-mode filters and in pulse and broadband transformers.

All toroidal cores are supplied burnished to break sharp edges.

Coating Options:

– Toroids with an outside diameter of 9.5 mm (0.375″) or smaller can be supplied Parylene C coated. The Parylene coating will increase the “A” and “C” dimensions and decrease the “B” dimension a maximum of 0.038 mm (0.0015″). The ninth digit of a Parylene coated toroid part number is a “1”. See reference tables for the material characteristics of Parylene C. Parylene C coating is RoHS compliant.

– Toroids with an outside diameter of 9.5 mm (0.375″) or larger can be supplied with a uniform coating of thermo-set plastic coating. This coating will increase the “A” and “C” dimensions and decrease the “B” dimension a maximum of 0.5 mm (0.020″). The 9th digit of the thermo-set plastic coated toroid part number is a “2”. Thermo-set plastic coating is RoHS compliant.

– Thermo-set plastic coated parts can withstand a minimum breakdown voltage of 1000 Vrms, uniformly applied across the “C” dimension of the toroid.

For any toroidal core requirement not listed in the catalog, please contact our customer service department for availability and pricing.

The C dimension may be modified to suit specific applications.

Weight: 4.7 (g)

| Dim | mm | mm tol | nominal inch | inch misc. |

| A | 12.7 | ±0.25 | 0.5 | _ |

| B | 7.9 | ±0.20 | 0.311 | _ |

| C | 12.7 | ±0.35 | 0.5 | _ |

Chart Legend

Σl/A : Core Constant, le : Effective Path Length, Ae : Effective Cross-Sectional Area, Ve : Effective Core Volume

AL : Inductance Factor

| Electrical Properties | |

| AL(nH) | 150 ±25% |

| Ae(cm2) | 0.299 |

| Σl/A(cm-1) | 10.4 |

| le(cm) | 3.12 |

| Ve(cm3) | 0.93 |

Toroids are tested for AL values at 10 kHz.

A high frequency NiZn ferrite developed for a range of inductive applications up to 25 MHz. This material is also used in EMI applications for suppression of noise frequencies above 200 MHz. Excellent stability characteristics.

Strong magnetic fields or excessive mechanical stresses may result in irreversible changes in permeability and losses.

Available in 61 material™:

EMI Suppression Beads

Beads On Leads

SM beads

Wound Beads

Multi-Aperture Cores

Round Cable Snap-Its

Toroids

Rods

Antenna/RFID

Rods

Round EMI Suppression Cores

61 Material™ Characteristics

| Property | Unit | Symbol | Value |

| Initial Permeability @ B < 10 gauss | µi | 125 | |

| Flux Density @ Field Strength | Gauss Oersted |

B H |

2500 15 |

| Residual Flux Density | Gauss | Br | 1000 |

| Coercive Force | Oersted | Hc | 1.2 |

| Loss Factor @ Frequency | 10 -6 MHz |

Tan δ/ µi | 90 10 |

| Temperature Coefficient of Initial Permeability (20 -70°C) | %/°C | .10 | |

| Curie Temperature | °C | Tc | >300 |

| Resistivity | ohm-cm | ρ | 1×108 |

**** Characteristic curves are measured on standard Toroids (18/10/6 mm) at 25°C and 10 kHz unless otherwise indicated. Impedance characteristics are measured on standard shield beads (3.5/1.3/6.0 mm) unless otherwise indicated.

Material Safety Data Sheet (MSDS)

Click here to download Complex Permeability vs. Frequency (CSV)

Click here to download 61 Material Power Loss Density vs. Flux Density at 25°C

Ferrite Material Constants

Storage and Operating Temperature

Printer Friendly Data Sheet - Download as pdf file