EMI Suppression Beads (2615000102)

15 SHIELD BEAD

15 Material

Suppression Components

Board Component

Printer Friendly Data Sheet

Check Stock

Part Number: 2615000102

15 SHIELD BEAD

Explanation of Part Numbers:

– Digits 1 & 2 = Product Class

– Digits 3 & 4 = Material Grade

– Last digit 1= Not Burnished 2 = Burnished

– The last digit of the Parylene coated part is a “4,” which is available upon request. The minimum coating thickness beads is 0.005 mm (0.0002″).

Fair-Rite offers a broad selection of ferrite EMI suppression beads with guaranteed minimum impedance specifications.

Our “Shield Bead Kit” (part number 0199000019) contains a selection of these beads.

For any EMI suppression bead requirement not listed here, feel free to contact our customer service for availability and pricing.

The C dimension, the bead length, can be modified to suit specific applications.

Weight: 0.1 (g)

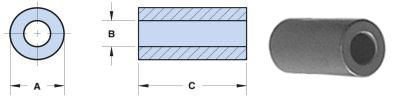

| Dim | mm | mm tol | nominal inch | inch misc. |

| A | 3.5 | ±0.20 | 0.138 | _ |

| B | 1.3 | ±0.10 | 0.051 | _ |

| C | 3.25 | ±0.25 | 0.128 | _ |

Chart Legend

+ Test frequency

• The column "H (Oe)" gives for each bead the calculated dc bias field in oersted for 1 turn and 1 ampere direct current. The actual dc H field in the application is this value of “H” times the actual NI (ampere-turn) product. For the effect of the dc bias on the impedance of the bead material, see figures 18-23 in the application note How to choose Ferrite Components for EMI Suppression.

| Typical Impedance (Ω) | |

| 10 MHz | 23 |

| 25 MHz+ | 29 |

| 100 MHz+ | 34 |

| 250 MHz | 39 |

| Electrical Properties | |

| H(Oe) | 2 |

Suppression beads are controlled for impedances only. Minimum impedance values are specified for the + marked frequencies. The minimum impedance is typically the listed impedance less 20%.

Single turn impedance tests for 73 and 43 material beads are performed on the E4990A Impedance Analyzer. The 15, 20 and 61 material beads are tested on the E4991A / HP4291B Impedance Analyzer. Beads are tested with the shortest practical wire length.

| Typical Impendance (Ω) | |

| 10 MHz | 23 |

| 25 MHz+ | 29 |

| 100 MHz+ | 34 |

| 250 MHz | 39 |

A new high permeability NiZn material developed for suppression and broadband applications. This material with its higher permeability than many other NiZn types provides high impedance levels extending down to 10 MHz. Optimal suppression frequency is 10-250 MHz.

Available in 15 material:

-Customer Specific Designs

-Multi-Aperture Cores and Shield Beads

15 Material Characteristics

| Property | Unit | Symbol | Value |

| Initial Permeability@B < 10 gauss | µi | 1500 | |

| Flux Density @ Field Strength | Gauss Oersted |

B H |

2700 10 |

| Residual Flux Density | Gauss | Br | 1800 |

| Coercive Force | Oersted | Hc | 0.2 |

| Loss Factor @ Frequency | 10 -6 MHz |

Tan δ/ µi | 15 0.1 |

| Temperature Coefficient of Initial Permeability (20 -70°C) | %/°C | 1.1 | |

| Curie Temperature | °C | Tc | >105 |

| Resistivity | Ω cm | ρ | 10 8 |

**** Characteristic curves are measured on standard Toroids (18/10/6 mm) at 25°C and 10 kHz unless otherwise indicated. Impedance characteristics are measured on standard shield beads (3.5/1.3/6.0 mm) unless otherwise indicated.

Material Safety Data Sheet (MSDS)

Click here to download Complex Permeability vs. Frequency (CSV)

Ferrite Material Constants

Storage and Operating Temperature

Printer Friendly Data Sheet - Download as pdf file